UNIPORT4000

Travelling bridge CNC machining centre

Uniport4000

- Multi-sided machining in single set-up

- Large working area – small footprint

Flexible all-rounder

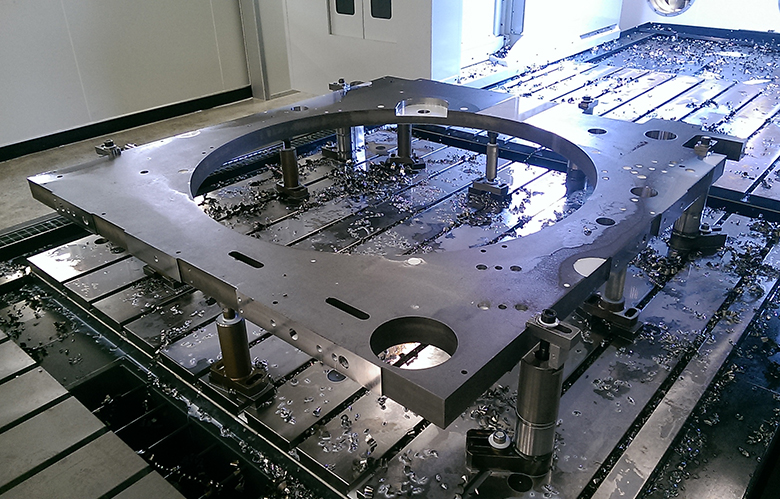

The UNIPORT4000 is the smallest model from our premium gantry machine series. It takes up relatively little space on the shop floor thanks to its travelling portal bridge. The UNIPORT4000 was already renowned for its outstanding vertical machining performance. But now with an even higher clearance plus a right-angular head available as an option its functionality has been expanded. Offering you even more flexibility and huge gains in processing times.

Benefits

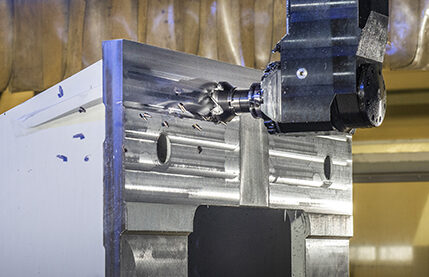

Right-angular head for multi-sided machining

You can work more efficiently with the new UNIPORT4000. Now there is no need for third-party commercial heads to perform horizontal machining. Just one right-angular head with automatic tool change allows you to machine your products from all sides. The head also increases the Z-axis range by up to 50% (up to 750 mm). The vertical clearance can even be up to 1250 mm.

Automatic tool changes

Changing tools manually in the right-angular head is now a thing of the past, as the UNIPORT4000 does it for you. The machine is equipped with a chain type tool store located in the moving bridge column as standard. If you need more tools, you can opt for a second tool storage mounted on the rear side of the portal bridge. In total, storage available for more than 100 tools.

Two work zones for higher spindle performance

For pendulum machining, the X-axis can be divided into two separate work zones. While you are machining a product in one zone, you can set up the next work piece in the other zone. This means you can be sure to get the most out of the spindle.

Technical specifications

This renewed CNC machine, the Uniport 4000, is available with two main spindle configurations, 36 kW at 12.000 rpm or 16.000 rpm. The main spindle is equipped with an HSK-63A.

Work area

- X-axis4.000 - 24.000+ mm

- Y-axis1.500 - 3.500 mm

- Z-axis500 / 600 / 750 mm

- Vertical clearance610 / 750 / 1.000 / 1.250 mm

- Width between column1.550 - 3.550 mm

Spindle

- Direct driven spindle36/58 kW

12.000/16.000 min-1

180 / 135 Nm

Various

- Tooling

- Taper sizeHSK-A63

- Number of pockets# 29-102

- Tool change time8 sec

- Speed

- Rapid traverse40.000 mm/min

- Feed Rate5 - 40.000 mm/min

Accessories

- Linear scaleso

- Pendulum modeo

- Tool measuring and tool break via lasero

- Siemens / Heidenhaino

CNC machine applications

- Logistics

- Energy

- General machining

We have established a world leading position in front axle machining. Truck manufacturers and suppliers use our UNITWIN CNC machine to produce more than 2 million front axles every year.

For the complex rear axle machining we also have a dedicated solution: our UNIAXLE. With this new CNC machine you can machine cast iron as well as steel welded rear axles to the greatest precision, in the shortest possible time, all in a single setup.

For everything from bogies to wheels and weld preparation to wheel carrier machining, Unisign has highly versatile machines like the Uniport6000 and Uniport7000. These gantry style machining centres are part of the machine tool program that have been designed to deliver extremely high capacity, dynamics, rapid acceleration and offer a generous working area.

applications for logistics

Heavy duty turning, milling and drilling characterises the production of components for energy-producing equipment like (wind) turbines. So you need a CNC machine that can take the load. A mill-turn machining centre like the Unicom6000, Unicom7000 and the Uniport7000-MTC or a multi-functional Uniport6000 and Uniport7000 are the ideal solution for producing these demanding parts.

Pumps and valves for the oil & gas industry can be highly complex parts to produce with seals, gaskets, flanges and requirements like spiral grooves and elliptical conical eccentric turning. The machining centres from Unisign, with their high degree of automation and specially designed software, are a unique solution capable of milling parts that others cannot.

At Unisign we understand that our customers don’t just buy a CNC machine, they buy a process. And price per part is key. So for general applications we offer high torque machines with high material removal rates, including 5-axis and 5-sided machining and a choice of moving table or palletized, depending on the footprint available.

applications for general machining