Customer stories

Stadler Winterthur - Switzerland

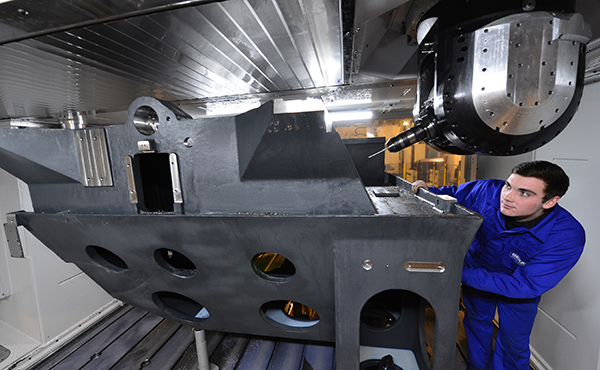

Bogies machined without a hitch thanks to Unisign

Application: Machining of train bogies

Machine type: UNIPORT7000 and UNIVERS

Bharat Forge Kilsta - Sweden

UNITWIN6000: innovative front axle machining

Application: Machining of front axles for trucks and buses

Machine type: UNITWIN6000

Medha Bogies Pvt. Ltd. - India

The perfect fit for bogie machining

Application: Machining of bogie frames for trains

Machine type: UNIPORT6000

AMA Anlagen- und Maschinenbau - Germany

Robust, reliable and user-friendly: the UNIPORT6000

Application: Machining of complex cast components and welded constructions

Machine type: UNIPORT7 | UNIPORT4000 | UNIPORT6000

BMA Braunschweigische Maschinenbauanstalt AG - Germany

UNIPORT6000 machines for greater machining efficiency

Application: Machining of large components for machines and systems

Machine type: UNIPORT6000 | UNIVERS6 | UNIPORT6

Heinz Baumgartner AG - Switzerland

UNIPORT6000-HV-OG boosts the flexibility and quality

Application: Machining large components

Machine type: UNIPORT6000-HV-OG

Gontermann & Simon - Germany

UNIPORT6000 – indispensable for high-precision machining

Application: 5-axis machining of large, complex components

Machine type: UNIPORT6000

De Rooy Slijpcentrum - the Netherlands

Succesful start in CNC milling market using UNIPORT machines

Application: Milling large machine parts

Machine type: UNIPORT4000 | UNIPORT6000

Hofmann Engineering - Australia

State of the art bogie machining on UNIPORT6000

Application: machining of bogie frames for trains

Machine type: UNIPORT6000

Palmse - Estonia

Increased production for PALMS forest trailers

Application: machining vehicle frames for forestry equipment

Machine type: UNIPORT6000

Brück GmbH - Germany

Unisign machines – the first choice for high-precision finishing

Application: finishing of special forged components (e.g. rings and flanges)

Machine type: UNIPORT6000 | UNIPORT7000 | UNIPORT8000 | UNICOM6000

ENGEL Austria GmbH - Austria

Total machining solution with 3 UNICOM6000 machines connected together via an FMS

Application: Complete machining of components for large injection-moulding machines

Machine type: UNICOM + FMS turnkey

STT Servis - Czech Republic

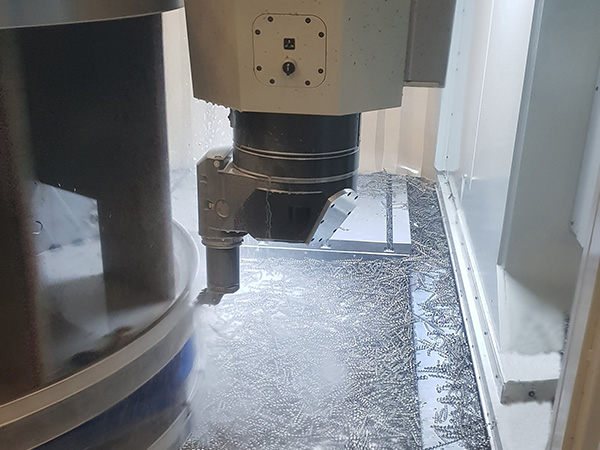

Increasing manufacturing speed with Unisign portal machining centres

Application: Machining large steel plates and weldments for machine parts

Machine type: UNIPORT4000 | UNIPORT6000

HOMAG GmbH, Schopfloch - Germany

Large, made-to-order components up to 12.5 m, processed down to smallest detail

Application: Machining of large parts for through-feed and stationary wood processing machines

Machine type: UNIPORT6000 | UNIPORT7000 | UNIPORT7 | UNIVERS6

Wilo Group - Germany

UNICOM6000 – indispensable for the production of large pumps

Application: Machining of large pump housings

Machine type: UNICOM6000

Rába Axle Ltd. - Hungary

Front axle beams exclusively machined on UNITWIN6000

Application: Machining front axle beams for trucks and agricultural vehicles

Machine type: UNIVERS | UNITWIN

HOMAG Kantentechnik GmbH - Germany

UNIPORT6000: the beating heart of the production process

Application: Machining base frames for edge banding machines

Machine type: UNIPORT6000

GEMAG Gelenauer Maschinenbau - Germany

High accuracy and process stability with Unisign machines

Application: Machining large mechanical components for machine tools

Machine type: UNIPORT6000-HV | UNIPORT7000-KW | UNICOM6000 | UNIPORT8000 | UNIPORT7

VDL Konings - The Netherlands

Performing multiple operations on complex welded structures

Application: Machining complex welded constructions for medical devices

Machine type: UNIPORT6000

Ferdinand Steck Maschinenfabrik AG - Switzerland

Universal machine for small parts and large components

Application: Machining of large and small chassis and undercarriage components for rail vehicles

Machine type: UNIPORT6000

ABB Turbocharging - Switzerland

Old NC programs operate 1:1 on new CNC machine

Application: Machining of industrial components for turbochargers

Machine type: UNICOM7000