New generation of steel telescopic covers for UNICOM6000 machines

June 18, 2024

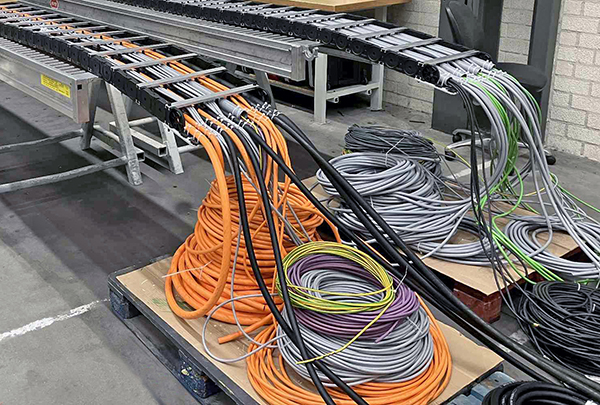

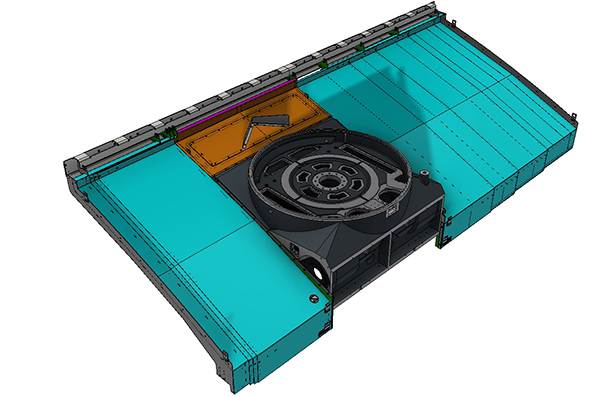

Our UNICOM6000 machines are fitted with a telescopic steel cover, also known as a Y-shaped steel telescopic cover. The cover ensures the slideways and drive are adequately protected against machining waste, dirt and coolant. The steel telescopic covers are moved along a parallel mechanism using chains.

Challenge

The steel covers are sometimes damaged when the machine is operated. Sections can deform due to the impact of falling objects or when operators accidentally step onto them. Previously we would always be able to replace the damaged components. However, from 2020 onwards, it became a real challenge to obtain replacement parts as the original manufacturer had stopped trading. So, we asked ourselves how we could still help clients who needed to have a Y-shaped telescope replaced.

Solution

At Unisign, we reached out to a new supplier called Hennig GmbH – a leading manufacturer in this area. Working closely together, we developed a new generation of Y-shaped steel telescopic covers. The outcome was an improved design that offers a range of benefits compared with the old covers.

Hennig GmbH, Mr Roderick Hennl (Managing Director) on the new development: ‘Individual machining technologies require customised machine protection to protect sensitive machine components. For over 70 years, Hennig has been working on sustainable machine protection solutions that are designed and produced in close cooperation with our customers. Together, Unisign and Hennig GmbH have also found the best possible solution to make our customers successful.”

Features of the new design

The new design has the following characteristics:

- Improved seal: The updated steel telescopic cover has an improved seal that stops practically all machining waste from getting in between the cover sections.

- Straightforward mechanism: The simplified guiding system has fewer moving parts to reduce potential faults, improving the durability of the cover.

Benefits

- Enhanced reliability: The improved design reduces faults and deformation, resulting in fewer interruptions in the manufacturing process and greater productivity.

- Longer life span: The new design has a durable construction to increase the life span of the steel telescopic cover, offering customers the benefit of long-term performance without frequent replacements or repairs.

- Increased efficiency: Customers can expect increased efficiency and an improved ROI thanks to the reduced risk of stoppages caused by machining waste and faults.

Conclusion

By launching an improved Y-shaped steel telescopic cover for UNICOM6000 machines, we have overcome the challenge of replacements and repairs, while improving machine performance and reliability. Our collaboration with Hennig GmbH marks the arrival of a new generation – an innovative solution that has already proved itself in practice.

In focus

Unicom6000

Specification

- X-axis1.950 mm

- Y-axis1.425 mm

- Z-axis1.000 / 1.250 mm