Leveraging local expertise in Czech Republic and Slovakia

August 26, 2024

In the competitive world of CNC machine tools, reliable and efficient service is paramount. Our collaboration with MRM Machinery, a local partner in the Czech Republic and Slovakia, highlights the advantages of integrating local expertise into our service model. This case study explains how this partnership enhances service delivery, offering significant benefits to our Czech and Slovakian customers.

About MRM Machinery

MRM Machinery is a distinguished supplier of CNC machine tools for metal chip machining, representing top-tier manufacturers such as Unisign. The MRM team comprises former employees of Czech machine tool manufacturers, bringing over 20 years of industry experience. They specialize in providing comprehensive services for larger, more complex technological units.

Scope of services

MRM Machinery offers a full suite of services for our Unisign CNC machines, including:

- Selection and procurement: Helping customers choose the right machine tools.

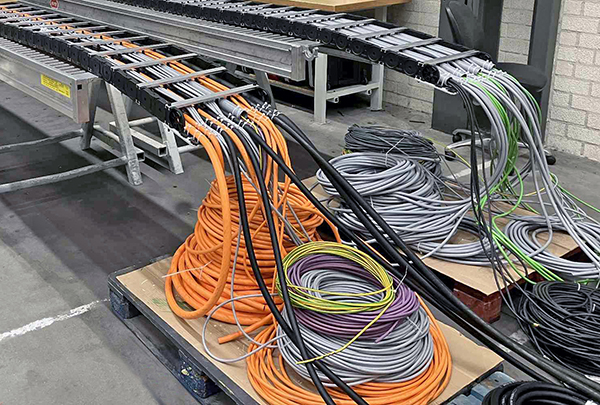

- Installation: Constructing foundations and implementing technology solutions for specific workpieces.

- Training: Offering operator and maintenance training, as well as programming courses.

- Service support: Providing extensive post-installation support, including warranty and post-warranty services, preventive maintenance, and original spare parts supply.

- Remote diagnostics: Establishing and operating remote diagnostic systems for machines with HEIDENHAIN and SIEMENS control systems.

Long-standing partnership with Unisign

Jan Šmíd, Service Manager at MRM Machinery, comments: “We have been partnering with Unisign since our inception in 2015. This collaboration has resulted in the installation of over 10 machines, particularly the successful UNIPORT series, which excels in machining welded structures. Initially we focused on securing business cases and marketing, the partnership however has expanded to include technical support and spare parts delivery. This was especially crucial in the post-COVID era.”

Enhanced customer benefits

Our collaboration with MRM Machinery offers multiple benefits to our customers in the Czech Republic and Slovakia:

- Elimination of language barriers: Local staff speak the customers’ language, ensuring clear and effective communication.

- Rapid response: Quick assistance over the phone or through remote diagnostics minimizes machine downtime.

- Reduced service costs: Local technicians mean faster response times and lower travel costs, reducing overall service expenses and downtime.

- Comprehensive support: Customers receive full support from machine selection to post-installation services, providing peace of mind and operational continuity.

Conclusion

Partnering with MRM Machinery exemplifies how leveraging local expertise can significantly enhance service delivery for the Unisign CNC machines. By ensuring quick, reliable, and comprehensive support, we provide our customers in the Czech Republic and Slovakia with a robust and efficient service experience. This collaboration not only meets but exceeds customer expectations, reinforcing our commitment to excellence in every aspect of our operations.