Additional machining head enhances production of forestry machinery

October 31, 2024

When Leif Fors founded his company in 1992, he could not have foreseen FORS MW growing into one of Europe’s largest production facilities for forestry and agricultural machinery. The Swedish family business is based in Estonia. Since the founder’s passing in 2015, his daughter Ulrica Fors has taken the helm. FORS MW manufactures forestry trailers, cranes, and agricultural machinery, with the majority of production occurring at the main facility in Saue. This location boasts a complete production facility where design, manufacturing, and assembly take place. Today, FORS MW has 250 dealers worldwide representing the company on an international scale.

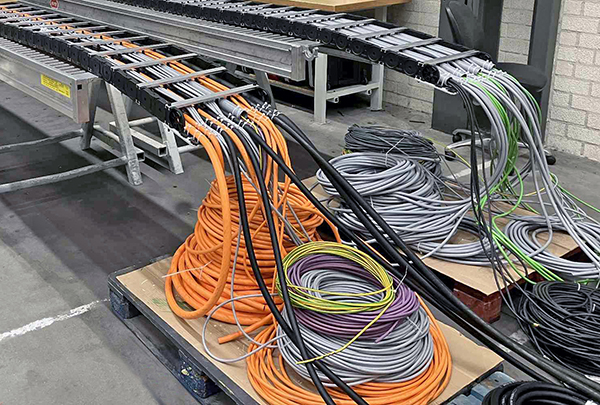

Since 2019, the family business has been utilizing a Unisign CNC machine. The UNIPORT6000 processes large components for trailers, cranes, and machines, playing an essential role in the production process. In November 2023, the CNC machine received an additional machining head, enhancing the machine’s speed and reliability.

Reliable local service

In 2019, FORS MW aimed to enhance the efficiency of their production processes while improving product quality. The UNIPORT6000 proved to be the ideal choice. “With the UNIPORT6000, we made a significant leap forward in our production process,” says Henry Lepik, Chief Production Engineer at FORS MW.

“We chose Unisign because other Estonian companies recommended this type Unisign machine and their services. Crucially, we knew we could rely on excellent local support. While Unisign is based in the Netherlands, they have a substantial support and service team in Estonia through an intermediary company (Nordcity) representing them in the region. Local service was crucial for us, as it ensures faster response times compared to having a service team fly in from another country.”

A perfect fit

FORS MW initially ordered the all-round CNC machine with a universal machining head only. After a few years, they discovered that adding an additional angular head could further enhance their production capabilities. “The universal head performed well, but the angular head suited our needs even better,” explains Lepik. “The new head operates at a 90-degree angle, which is perfect for our predominantly side machining operations. It also eliminates the need to rotate on an additional axis, saving us time. With the new head, we’ve reduced our overall program time by up to 25 percent.”

The new angular head not only operates faster but also with greater precision, Lepik adds: “The angular head is even more accurate than the universal one. We verify head alignment every morning, and it consistently meets our tolerances.”

Never stop delivering

Operating with two heads reduces the risk of downtime. If one head encounters an issue, production continues seamlessly using the other. “Such incidents are rare,” says Lepik. “But when they do occur, we simply switch to the other head, resume where we left off, and maintain our product delivery schedule.”

Continue work the same day

Recently, there was an incident involving a crash with the new machining head due to a mispositioned storage box, resulting in a collision. Lepik explains: “It was an unforeseen circumstance. Both our team and Unisign were caught off guard, but Unisign quickly identified the root cause. They adjusted the PLC program to prevent the machine from moving too far toward the storage box. We were able to resume operations the same day.”

Excellent service

When Lepik needs assistance, he receives a response within a day. “I usually liaise with Unisign’s partner in Estonia,” he says. “They communicate with Unisign on our behalf and provide us with solutions promptly. In my experience, their service is excellent—they’ve consistently resolved all our issues. Since Unisign manufactures all their machines in-house, they have an in-depth understanding of their product. They’re highly knowledgeable and responsive to our queries.”

In focus

Uniport6000

Specification

- X-axis4.000-24.000+ mm

- Y-axis1.500-5.000 mm

- Z-axis1.000 / 1.250 mm