Ensuring optimal machine uptime with a maintenance contract

December 11, 2024

With over 150 years of expertise in forging technology, SCHÖNEWEISS & CO GmbH is a leading specialist in precision drop-forged safety components and complex forged parts. As a trusted partner to the truck and commercial vehicle industry, the company sets benchmarks in components with exceptional technical requirements.

With a dedicated team, SCHÖNEWEISS manufactures chassis parts such as front axles, suspension components, steering parts, engine and transmission components, as well as substitute parts. The combination of deep expertise, a broad product range, and state-of-the-art manufacturing technology has earned the trust of renowned OEMs such as Daimler Truck AG, Volvo Trucks, Scania, and MAN.

Manufacturing front axles

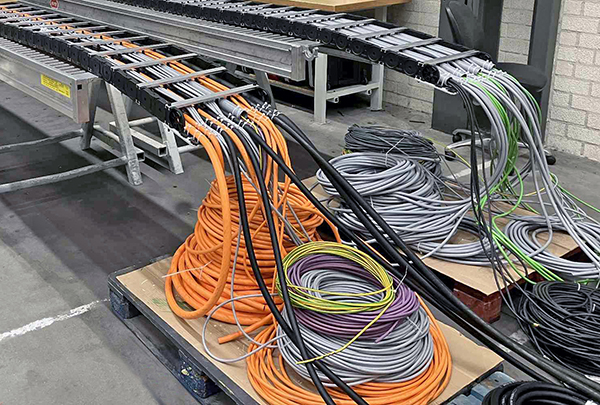

For over two decades, SCHÖNEWEISS has relied on CNC technology from Unisign to meet the industry’s high standards. Currently, two CNC machining centers, each equipped with two Univers6 machines, are in operation. These machines are heavily utilized for the machining of truck front axles.

The components are manufactured within the tightest tolerances, from pre-machining to final processing. To maintain this precision and reliability over the long term, SCHÖNEWEISS opted for a maintenance contract with Unisign in 2021.

Maintenance contract: a guarantee for availability

Under the maintenance contract, the machines are serviced twice a year by experienced Unisign technicians. This includes comprehensive inspections as well as necessary maintenance tasks. The aim is to ensure maximum machine availability and seamless production at the highest level.

Experience with Unisign service

The maintenance contract is consistently rated positively by SCHÖNEWEISS. Mr. Altena, Maintenance Coordinator at SCHÖNEWEISS, explains: „The service work is always effective and meets our company’s high standards. The Unisign technicians are competent and work with great expertise. If an issue arises, it is resolved quickly and successfully in close collaboration with Unisign.“ SCHÖNEWEISS particularly emphasizes the quality of the technical support and machine maintenance.

Powerful and reliable

Unisign machines are regarded as powerful and reliable by SCHÖNEWEISS. Mr. Altena adds: „Of course, like any machine manufacturer, there are specific strengths and weaknesses—for example, in design. Nevertheless, the results meet our high expectations. In 95% of cases, Unisign’s response time is fast and satisfactory. Spare parts delivery is also reliable and efficient.“

Conclusion: a partnership that sets standards

The longstanding collaboration between SCHÖNEWEISS & CO GmbH and Unisign demonstrates how a strong partnership can drive innovation and efficiency in manufacturing.

Unisign’s reliability, the high quality of spare parts, and the fast response time to inquiries and issues are particularly appreciated. The combination of high-quality technology and dedicated service—supported by the maintenance contract—enables SCHÖNEWEISS to ensure high machine availability, meet production targets, and maintain the highest quality standards.