October 7, 2021

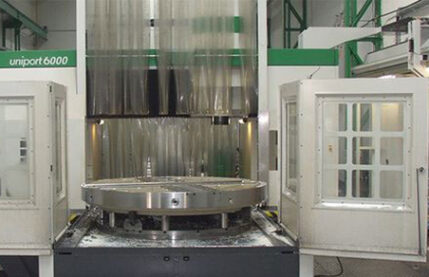

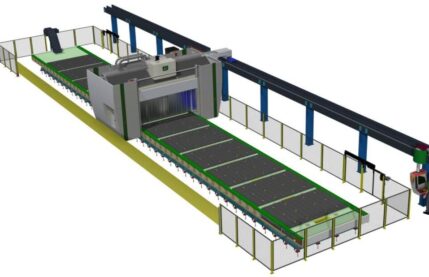

We have launched our revolutionary new CNC machine for the truck industry: the UNIAXLE.

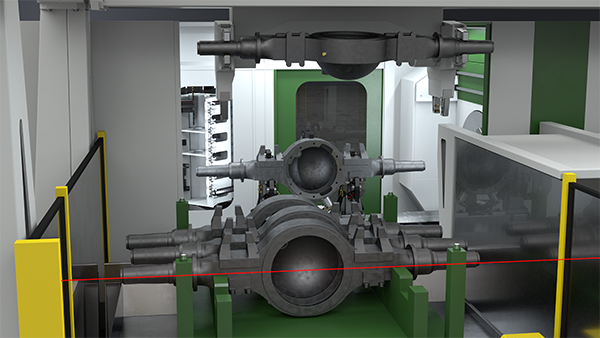

A dedicated CNC machining centre where welded and cast rear axles can be machined in a single setup. It will improve the accuracy and quality of rear axles. Production processes will be quicker and more cost-effective.

Learn more! Download our interesting UNIAXLE webinar

Ideal balance achieved

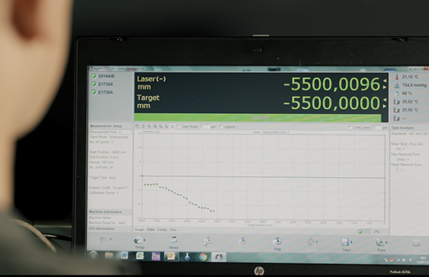

When developing the UNIAXLE, we found the ideal balance between accuracy, speed and stability. A truck rear axle contains a great deal of functionality and is far from symmetrical around its axis. When machining parts such as rear axle ends, there is considerable imbalance. Normally, this would mean working at low speed. But machining at a low rotation has an adverse effect on the processing time and machining conditions. The UNIAXLE CNC machine ensures accurate and fast machining without compromise.

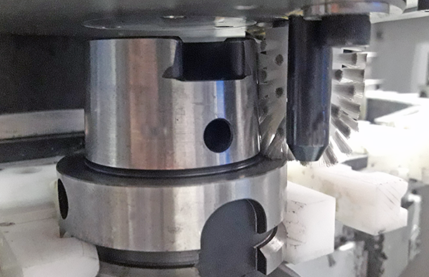

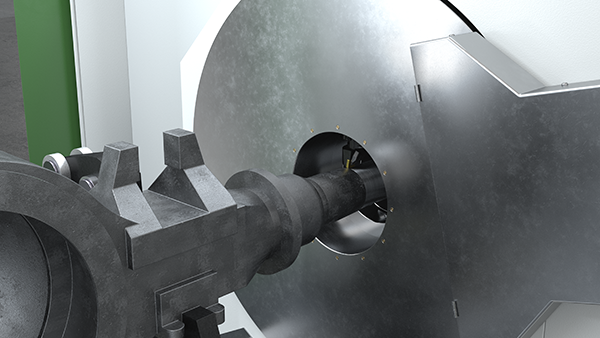

Innovation – turning head

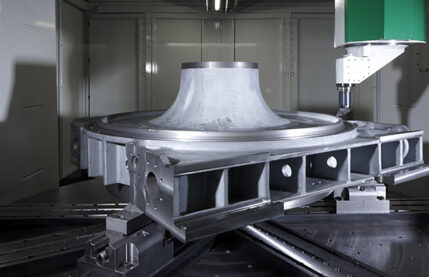

The UNIAXLE is a unique development because it’s not the rear axle in the CNC machine that rotates, but the cutting tool that rotates around the rear axle. The turning head is an innovation from our own R&D department. With this well-thought-out structural design, Unisign engineers have eliminated the imbalance in the rotating tools. Manufacturers can machine rear axles at high speed and very accurately.

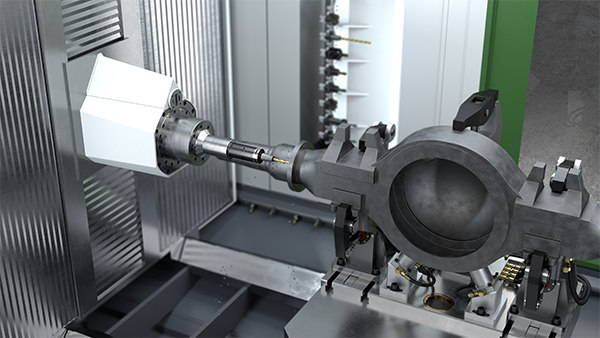

Simultaneous milling and turning

In addition to the unique turning head, the UNIAXLE also has a milling spindle. All turning and milling operations on the rear axle are carried out at the same time. For example, while an axle end is being created at the left, a flange is being milled at the right. Another advantage is the rotation unit which turns the rear axle through 90 degrees so the milling spindle can also machine the rear axle banjo.

Single clamping

A traditional production line with multiple machines requires many different operations. The frequent lifting, moving and setup operations influence the lead time as well as the accuracy of the machining. Single clamping means greater process reliability and a significant reduction in changeover times. These are also important advantages of having all-in-one machining on our UNIAXLE CNC machine.

UNIAXLE benefits

• All machining in one setup on a single machine

• Cycle time 30 min/axle (13,000 rear axles/year)

• Wide range of rear axles

• High machining speed

• High accuracy

• No imbalance

• Unmanned machine

• Maximum machining reliability thanks to fewer operations

• Takes up less space

• High efficiency with automatic loading crane

Are you interested and need more info? Mail to: [email protected]

In focus

Uniaxle

Specification

- X-axis700 mm

- Y-axis700 mm

- Z-axis1250 mm